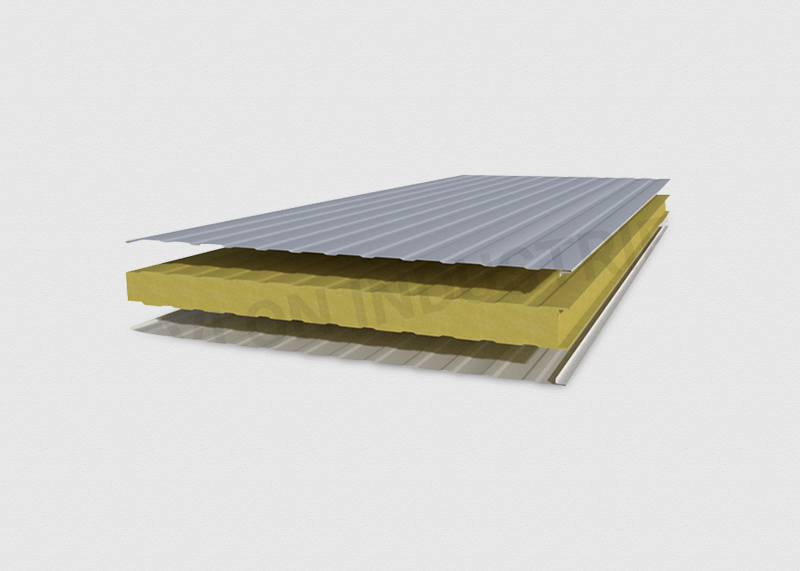

Honeycomb Puf Panel

Honeycomb Puf Panel is specified wherever high strength-to-weight ratio, energy absorption or directional qualities are desired. Honeycomb Puf Panel core is manufactured and offered in different configurations of cell diameters, thicknesses and densities. Wherever there is a requirement for greater structural strength with less weight, you will find Honeycomb Puf Panel Composite Panel to be the product of choice.

Features:

- Thermal Protection with ~0.44 (W/mK)

- Termite proof

- Easy insulation

- High Strength to weight ratio

- High Thermal & Sound insulation properties.

- Impervious to Fire / Water / Insects / Mold / Mildew.

- High mechanical properties

- Light weight

- Superior Flatness

- Light Weight

- Unparalleled Rigidity

- Fire & moisture Resistant

- Sound and Heat Insulation

- Corrosion Resistant

- Environmentally Friendly

- Wide Selection of Finishes and Dimensions

Applications:

- Aircraft Bodies

- Airports

- Buildings

- Prefab Houses

- Rail Interior & Coach Bodies

- Submarine Body Interior

- Panels for Elevator

- Partition walls and structures

- Roofing

- Furniture

- Exterior as well as interior walls of airports and railway stations for better acoustical and heat insulation, good impact resistance and radiation proof.

- Exterior walls of factories for better safety and flexibility exterior applications.

- Large module walls and floors requiring high technical performance.

- Temporary interiors such as exhibitions and showrooms.

- Walls & Floors in elevators.

- Board and yacht interiors.

- Furnishing (counter-tops, panels etc) sliding walks, ceilings.

- Large size panels easily installed without adhesive.

- Prefabricated bathroom cabins for hotels, cruise luxury bath and yachts

- Stainless steel honeycomb uses include joiner panels, bulkheads, train doors and floors or any areas where honeycomb is subjected to hostile environments.