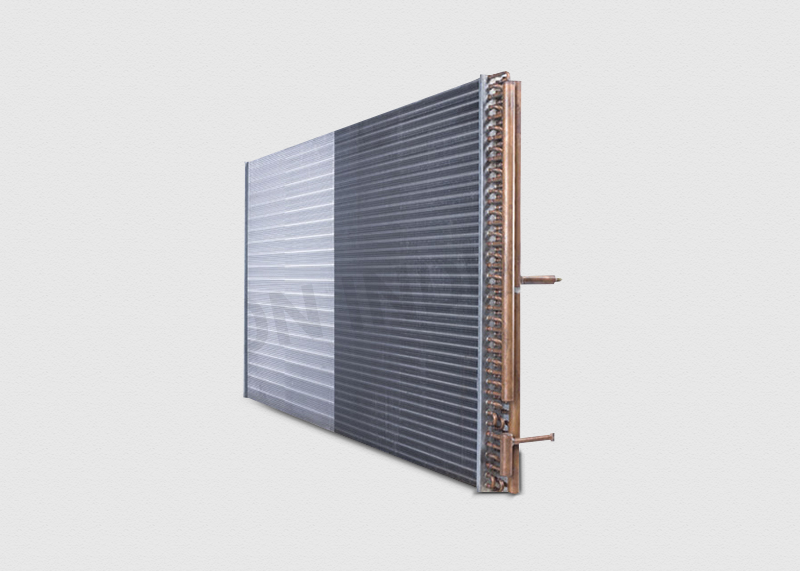

DX Coil / Steam Coil / Condenser Coil

DX Coil / Steam Coil / Condenser Coil is manufactured by us for various type of systems with water or glycol. The circuiting design makes coils drainable while we offer standard vents and drain for all header coils. As per application requirements, we can manufacture and provide casing, fin material, and circuiting in customized forms.

Materials Of Construction

Fin

- Corrugated plate type, die-formed

- Full-drawn collars for accurate control of spacing and maximum tube contact

- Standard Aluminum fin 0.13mm thick with optional (0.15mm).

- Optional copper and Blue coated fins thicknesses available are (0.12mm) (0.13mm) and (0.15mm).

- Fins per inch: 4 to 12

Tubes: Copper / S.S 304 / 316 / MS

Hairpin at one side of coils

Return bends : Seamless copper tube with 0.91mm thick

Mechanically expanded Tubes forming interference fit with fin collars

Specifications

- 5/8" O.D. x 0.42mm wall thickness standard with optional wall thickness of (0.56mm) (0.71mm) and (0.91mm).

- 1/2" O.D. x 0.42mm wall thickness standard with optional wall thickness of (0.56mm) (0.71mm) and (0.91mm).

- 3/8" O.D. x 0.42mm wall thickness standard with optional wall thickness of (0.56mm) (0.71mm) and (0.91mm).

- Rows available : 2 to 14

Headers

- Strong Brazing Joints with MS, copper or Stainless steel header offering parallel surface to coil tube.

- Vertically mounted coils and horizontally running tubes in circuiting designed for gravity-drain

Casing

- Flanges : 16-gauge minimum thick material, die-formed for easy mounting and stacking

- Coils over 44" fin length having intermediate tube supports with additional support every 42" multiple

- Material Options : Galvanized steel standard. Optional SS, aluminum and copper.

Brazing

- Joints : High temperature filler metals. At least 5% silver brazing in manifold connections

Testing & Performance

Coil assemblies are tested at 400 psig

Dry nitrogen used

Submerged under water

Standard construction suitable for

- Pressure : 250 PSI

- Temperature : Up to 300 degrees F